Introduction

Before there were automated controls, managing the flow of water, steam, or gas was done by hand.

Think back to the days of steam engines, those massive machines depended on steady pressure, and to keep that pressure in check, one small but powerful device played a key role and that was the globe control valve. It has been around since the industrial revolution, trusted to open, close, or regulate fluid flow with precision.

Now, even though technology has moved forward, globe valves have not become outdated, they have become essential.

You have probably used one without realizing it. That outdoor water tap you twist to control pressure? That is a globe control valve. And at the same time, globe valves are working to control complex flow systems in industries like power plants, oil and gas, petrochemicals, or building HVAC systems.

This blog is about understanding why globe valves are still trusted after more than 200 years. If you’re looking for the right globe valve supplier, understanding the full picture helps you make a proper choice.

Because when it comes to flow control, reliability is essential!7

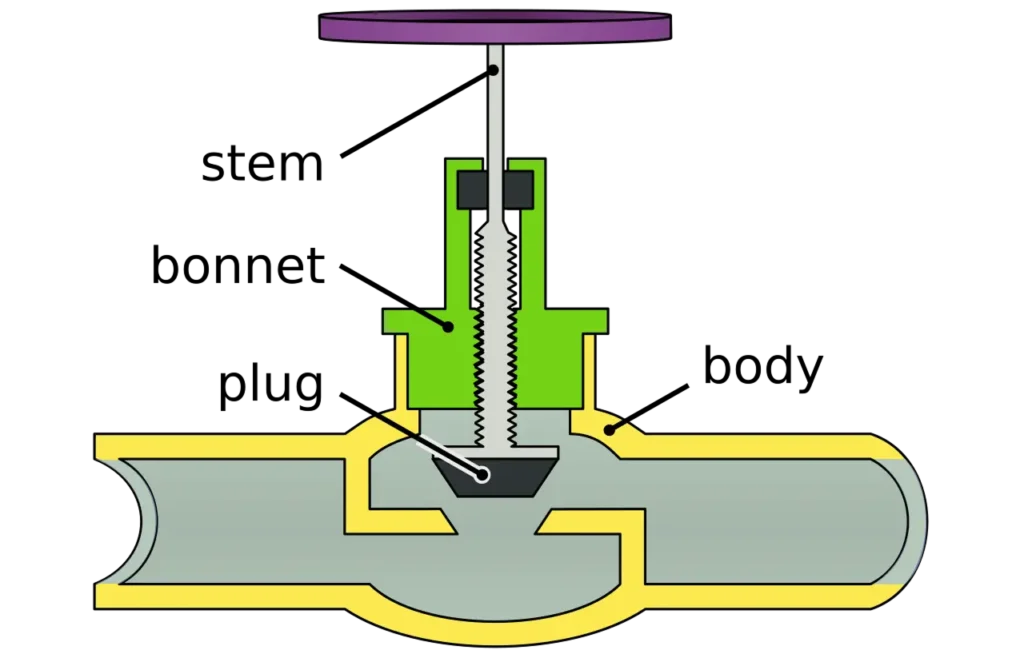

What are the Key Components of a Globe Valve?

The components of a globe valve include the stem, bonnet, plug, and body!

Source : Wikipedia

1) Body

The body is the main pressure-containing structure of the valve and is the most easily identified as it forms the mass of the valve. It contains all of the valve’s internal parts that will come in contact with the substance being controlled by the valve.

2) Bonnet

The bonnet provides a leak-proof closure for the valve body. The threaded section of the stem goes through a hole with matching threads in the bonnet. Globe valves may have a screw-in, union, or bolted bonnet.

3) Plug Or Disc

The valve’s closure mechanism involves plugs that connect to a stem, which is adjusted either by sliding or screwing it up or down to regulate flow.

3) Stem

The stem connects the actuator to the inside of the valve and transmits this actuation force. Stems are either smooth for actuator-controlled valves or threaded for manual valves.

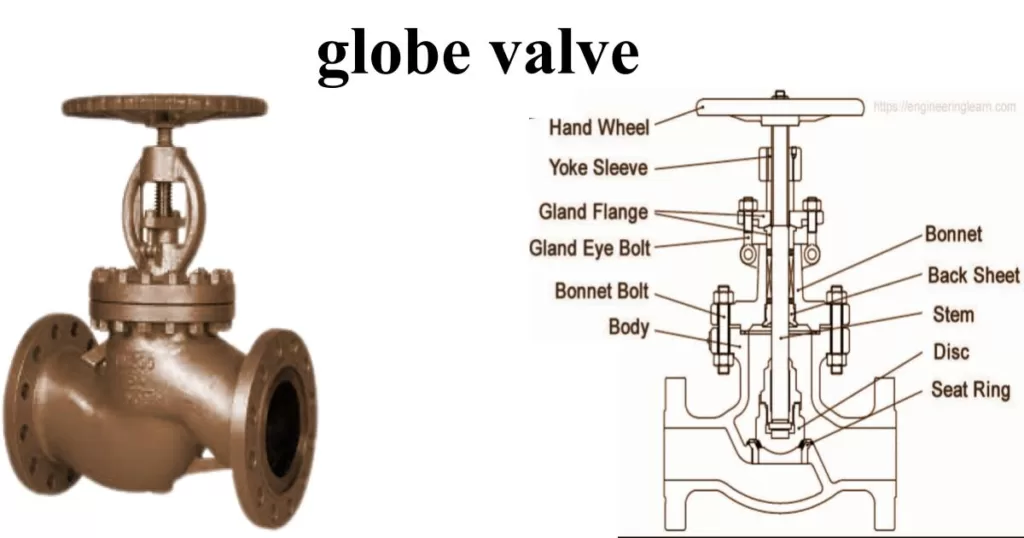

How Does a Globe Valve Work?

Source: Growmechnical

A globe control valve works by using globe valve parts, such as a movable plug or disc that presses down onto a seat to control flow. When you turn the handwheel, the stem moves the disc up or down. Lifting the disc allows fluid to pass through; lowering it blocks or reduces the flow. Its shape like a globe forces the fluid to change direction, which helps slow it down and gives you better control.

Globe valve uses a disc (like a plug) to stop, allow, or control the flow of fluid.

1) Closed Position:

When the valve is closed, the disc is pressed tightly against the seat (the opening), so no fluid can pass through.

2) Opening the Valve:

Turning the handwheel counterclockwise lifts the disc off the seat. As the disc rises, fluid starts flowing.

3) Flow Control:

The higher the disc is, the more fluid can pass. The lower it sits, the less fluid flows. This makes globe control valves great for controlling flow, not just stopping or starting it.

4) Closing the Valve:

Turning the handwheel clockwise lowers the disc back onto the seat, blocking the flow again.

Types of Globe Valves

Not all globe valves are built the same. Their shape changes how they work, how much they resist flow, and how easy they are to maintain.

| Type | How it looks | Flow path | Works best for |

| 1. Standard Globe Valve ( Z-type) |

Like a “Z,” the stem is vertical, and the flow path bends twice. | Fluid enters → turns up 90° → hits the disc → turns down 90° → exits. Flow Movement: Zig-zag Impact: More pressure drop due to sharp turns. |

General shut off |

| 2. Y- type Globe Valve | The body and stem are angled around 45° – like a tilted “Y”. | Fluid enters at an angle (about 45°) → passes through the tilted seat → exits without sharp turns. Flow Movement: Angled and smoother Impact: Less pressure loss, smoother flow than Z-type. |

Continuous high-temp/pressure |

| 3. Angle Globe Valve | The inlet and outlet are at a 90° angle. | Fluid enters → makes one 90° turn (up or to the side, depending on layout) → exits. Flow Movement: L-shaped Impact: Less piping needed; moderate pressure loss. |

90° turns, space-limited areas |

| 4. 3 – Way Globe Valve | T-configuration – one inlet, two outlets (or vice versa). | Flow Path Options: Diverting: 1 inlet → splits to 2 outlets (A → B & C) Mixing: 2 inlets (A & B) → combine to 1 outlet (C) Flow Movement: T-pattern Impact: Used for mixing fluids or switching directions. |

Mixing/diverting flows |

| 5. Vacuum Jacketed Globe Valve | Like Z-type, but with a vacuum-sealed jacket around it. | Same as Z-type (zig-zag path), but inside an insulated vacuum layer. Flow Movement: Protected Z-path. Impact: Minimizes temperature change in cryogenic fluids. |

Cryogenic fluids |

| 6. Steam Jacketed Globe Valve | Valve body enclosed in a steam-heated jacket. | Again, Z-type path, but with hot steam circulating around the valve body. Flow Movement: Heated zig-zag. Impact: Keeps sticky/thick fluids warm and flowing. |

Viscous or heat-sensitive fluids |

| 7. Forged Globe Valve | Smaller, compact, stronger build (usually Z-type). | Usually the same as standard Z-type, but with a tighter, stronger forged body. Flow Movement: Compact zig-zag. Impact: Handles higher pressure safely. |

High-pressure applications |

| 8. Fabricated Globe Valve | Custom-built from welded parts. Custom-built can be Z, Y, or Angle, depending on the design needs. | Flow Movement: Tailor-made. Impact: Designed around the specific flow path required. |

Custom engineering setups. |

Technical Comparison of Globe Valve Types

| High-Valve Type | Flow Resistance | Pressure Drop | Space Saving | Customizable |

| Z-Type Globe | High | High | Low | Moderate. Standardized design allows for some customization. |

| Y-Type Globe | Low | Low | Medium | Yes |

| Angle Globe | Low | Lower | High | Yes |

| 3-Way Globe | Low | High | High | Yes |

| Vacuum Jacketed | Low | Low | High | Yes |

| Steam Jacketed | Low | Low | Medium | Yes |

| Forged Globe | High | High | Compact | Yes but limited |

| Fabricated Globe | Depends on the design, but it’s high. | High | Yes | Fully |

Advantages of Globe Valves

Simple design makes them easy to manufacture, install, and maintain.

Short stem travel means quicker opening and closing times.

Provides reliable sealing for leak-proof performance.

Low wear on internal parts ensures long service life.

Allows precise flow control for throttling applications.

Operates safely under high-pressure or high-temperature conditions.

Easy to automate or control with actuators for remote operation.

Applications of Globe Valves

Globe valves are trusted across industries where precision flow control, isolation, and safety are important. Here’s how they deliver value in each sector:

1) Oil & Gas

Globe valves are essential in upstream and midstream oil operations. They regulate fluid flow, control pressure surges, and manage injection rates. They are often installed in test separators, flare systems, and flowlines.

2) Petrochemical

Refineries and petrochemical plants use globe valves in units that require steady, repeatable control, such as catalytic crackers, reboilers, or alkylation systems.

Many fluids here are corrosive or volatile, and globe valves offer the controlled actuation needed to smooth process parameters without leaks or fluctuations.

3) Pulp & Paper

Pulp mill processes, from digesters to bleaching stages, rely on valves that can handle fibrous slurries, chemicals, and steam. Globe valves are often used to regulate steam flow, which affects pulp consistency and dryness. In bleaching lines, they control harsh chemicals like chlorine dioxide or peroxide.

4) Power Plants

From coal-fired, nuclear, or combined cycle plants, globe valves are integral to feedwater control, boiler management, and turbine steam regulation. These systems demand quick-acting, reliable valves to avoid dangerous overpressurization.

5) LNG (Liquefied Natural Gas)

Globe valves are often cryogenic-rated in LNG terminals and storage tanks, managing flow at temperatures below -150°C. They regulate gas transfer during liquefaction and vaporization, preventing vapour lock or sudden pressure spikes.

6) Chemical Processing

In chemical plants, flow conditions often change rapidly requiring valves that respond quickly, safely, and precisely. Globe valves control dosing chemicals into reactors, manage cooling water loops, and help avoid cross-contamination between process lines.

7) Pharmaceuticals

Pharmaceutical environments demand valves that meet cleanroom and sanitary standards. Globe valves are used for batch fluid regulation, sterilization-in-place (SIP), and water-for-injection (WFI) systems. They provide smooth control without fluid stagnation.

8) Space Research & Aerospace

Globe valves handle gases like helium or hydrogen, cooling fluids, and oxidizers in aerospace testing labs and launch systems. They provide critical control in systems where even milliseconds of delay or tiny pressure changes can affect outcomes.

9) Mining & Metals

Used in cooling water systems, steam lines, and chemical addition in ore processing, globe valves must withstand abrasive flows and dust-heavy atmospheres. Their ability to throttle flow without full actuation makes them ideal for frequent, low-maintenance operation.

10) Industrial Gases & Cryogenic Systems

These systems require valves that can precisely meter flow under extremely low temperatures and avoid freezing or cavitation. Globe control valves with vacuum or steam jackets are often used in oxygen, nitrogen, and argon lines.

11) Food & Beverage

Globe valves are used in steam injection, cleaning-in-place (CIP) lines, pasteurization, and flavour dosing in F&B processing. They must handle high temperatures and be easy to clean. Stainless-steel sanitary globe valves meet these needs with minimal dead zones.

12) Sugar Plants & Distilleries

These facilities rely on steam for boiling, condensing, and fermenting. Globe valves provide the control needed to maintain stable pressure in boilers and condensers, directly impacting product yield and energy usage.

How to Choose the Right Globe Valve?

1) Know Your Flow Requirement

Globe valves are ideal if your system requires frequent throttling or precise flow control. However, considering the flow rate and direction, standard globe valves cause a pressure drop, which may not suit high-flow systems unless designed accordingly.

Understand the Operating Pressure and Temperature

2) Understand the Operating Pressure and Temperature

Globe valves come in forged or cast bodies with different pressure classes. Make sure the valve can withstand your system’s maximum pressure and temperature range, especially in steam, LNG, or cryogenic applications.

3) Consider the Fluid Type

Globe valves come in forged or cast bodies with different pressure classes. Make sure the valve can withstand your system’s maximum pressure and temperature range, especially in steam, LNG, or cryogenic applications.

Consider the Fluid Type

4) Choose the Right Valve Type

Is your media corrosive, abrasive, viscous, or clean? This impacts both material selection (SS, brass, alloy) and internal trim design (hard-faced seats, Teflon seals, etc.)

Different globe valve types suit different installation and flow needs:

Z-type: Best for tight shut-off and general use

Y-type: Lower pressure drop, ideal for high-frequency throttling

Angle type: Compact and good for directional flow change

Cryogenic jacketed: Required for ultra-low temperatures

Jacketed (steam/oil): Keeps fluid from solidifying (e.g., wax, bitumen)

5) Actuation Method Matters

Consider this question: Should the valve be operated manually, pneumatically, or electrically? Choose actuation based on accessibility, speed of response, and system automation.

Maintenance and Service Access

6) Maintenance and Service Access

If downtime is costly, go for designs that are easy to dismantle and maintain. Bolted bonnets and top-entry designs simplify seat and disc inspection or replacement.

7) Check Standards and Certifications

Ensure the valve complies with API, ASME, BS, or ISO standards relevant to your industry. Pharma, LNG, food, and nuclear sectors have stricter design and testing norms.

FAQ’s

1) What is the primary function of a globe valve?

A globe valve is primarily used to start, stop, and regulate fluid flow in a pipeline. Its design allows for precise flow control, making it ideal for applications requiring throttling or frequent adjustments.

2) How does a globe valve differ from other types of valves?

Unlike gate valves (which are mainly for on/off service) or ball valves (which offer quick shut-off), globe valves have a spherical body with a movable disc and a stationary ring seat. They enable better flow regulation but with a higher pressure drop.

3) Can globe valves be used for both liquid and gas applications?

Yes, globe valves are versatile and can handle both liquids and gases. However, material and design must be selected based on pressure, temperature, and fluid compatibility.

4) How do I choose between 2-way and 3-way globe valves?

2-way globe valves control flow in a straight line (inlet to outlet) and are best for simple shut-off or throttling.

3-way globe valves have multiple ports for flow diversion, mixing, or bypass applications, making them suitable for complex flow paths.

Conclusion

When it comes to globe valves, you need reliability, precision, and durability, and MASCOT Valves delivers all three. Leaks, pressure drops, and sudden shutdowns cost you time and money, and that is why you just do not need “GLOBE VALVE” you need the right one.

Our decades of expertise, careful and thorough testing, and commitment to quality ensure that every valve we produce is built to surpass its performance.

Get in touch today and experience the MASCOT difference.